Get A Free Quote

Note: You can also contact us by Email: [email protected]

Welded Through Hole Type Cylinders-WP-300PSI

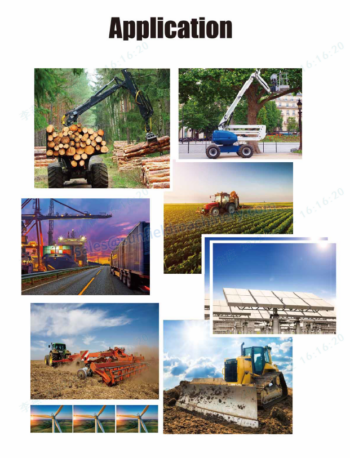

Our specialized staff is available for technical consultancy on your project and the best type of materials to use based on your application. We primarily work “on drawing,” preparing personalized projects according to customer needs.

Once the project is defined, we produce our technical drawing using CAD 2D-3D systems and supply it to our customer for approval.

Accurate raw materials and seal selection save costs and allow the production of high-quality and robust cylinders. For that reason, when choosing materials, we consider the cylinder's application field and the environment where it will work.

Specifically for chromed bars and tubes, we work only with producers or reliable suppliers.

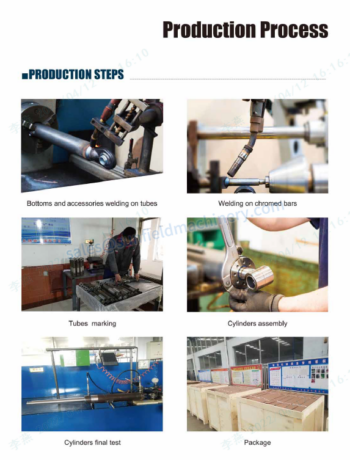

We produce about 120.000 hydraulic cylinders annually, and the whole process develops in our factory: cutting raw materials, turning and milling machining, components and accessories welding, cylinders mounting, and final testing.

All the above steps are made with the latest generation CNC machines, welding robotized stations, and specially-made equipment. Each step of production is controlled, and its progress is monitored with a “production tag” filled up by the operator at the end of each process. Each hydraulic cylinder is marked with a product code and several production orders for full traceability.

All hydraulic cylinders are controlled during the assembling for possible defects of the components used and tested with the “method of variation of pneumatic pressure” for possible leakage; by sampling or on customer request, cylinders are hydraulically tested on pressure.