Get A Free Quote

Note: You can also contact us by Email: [email protected]

“H” Class Mill Chains js an extremely strong, serviceable chain originally designed for heavy drives and transfer conveyor purposes in saw mills and the paper and pulp industry.

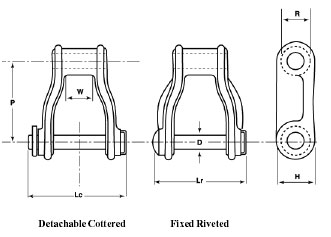

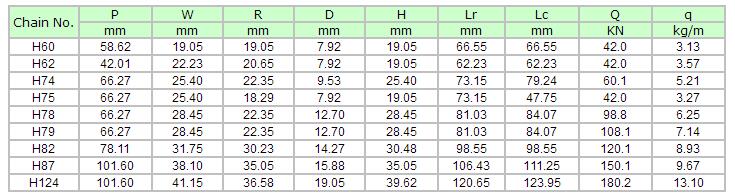

“H” Class Chain has proven itself for innumerable other industrial applications as well, especially for moderate duty in abrasive atmospheres where heavy, rugged chain is required. The sidebars of the “H” Class links are reinforced with wearing shoes which strengthen and stiffen the links when it is operated in troughs or over floors and runways. Pin holes are precision cored to assure accurate pitch sizes, which range from 2.308 to 4.000 inches. “H” Class Chain is available in both riveted and cottered construction. T-head pins engage two lugs cast on the links’ sidebars. This configuration prohibits pin rotation during chain operation, eliminating abrasive wear and pitch elongation.

“H” Class Chain conforms to manufacturer’s standards and is completely interchangeable with chains of other manufacturers. “H” Class Chain is available in Promal (Duramal) with tensile ranges of 9,450 to 40,500 pounds.

“H” Class Chain may operate in two directions. As a drive chain, it travels in the direction of the closed barrel; for elevator or conveyor applications, it should travel toward the open ends of the links.

Brutaloy or cast steel sprockets are available to accommodate every “H” Class pitch size. A wide assortment of attachments is also available for varied chain applications.

MATERIAL

The “H” Class Mill Chain are links cast of malleable iron or Promal (Duramal). It is a heat treated malleable iron having greater strength and superior resistance to wear and abrasion. Promal (Duramal) chains have heat treated pins.